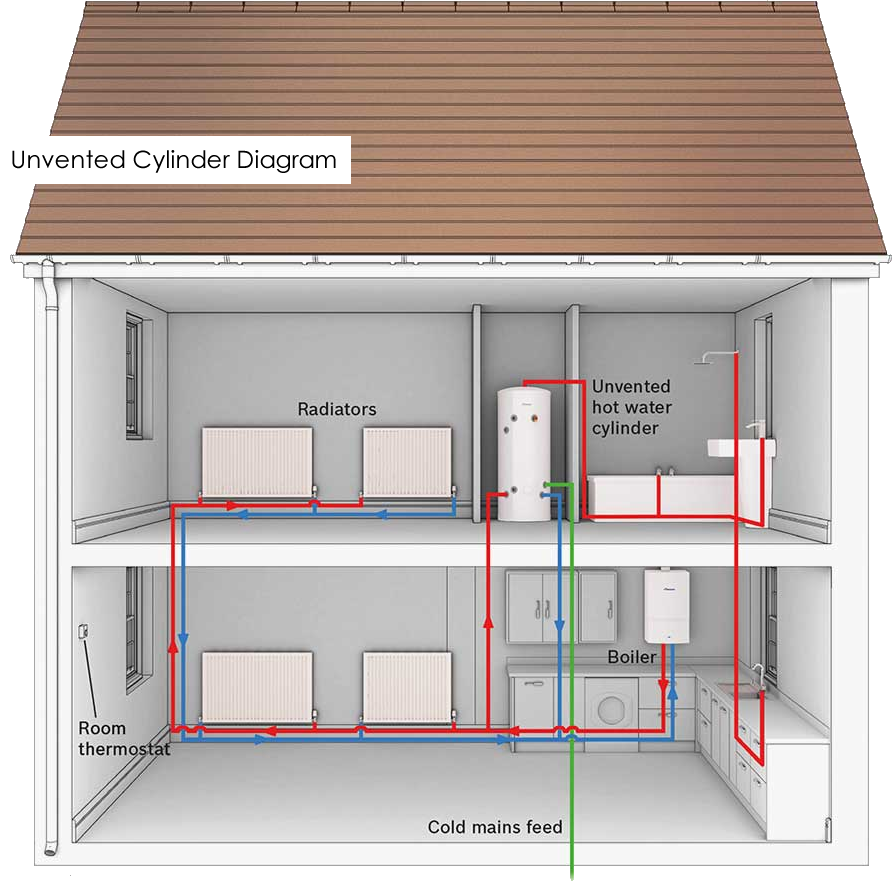

Unvented cylinders are a replacement for the traditional open vent hot water cylinder.

The traditional open vent cylinder requires a cold water storage cistern above it to provide a supply of cold water to replace the hot taken from the cylinder. In addition a vent pipe from the hot cylinder/ pipe work terminates over the cold water storage cistern to provide a safety outlet in the case of excess temperature expansion.

The hot water pressure and flow generated in a traditional cylinder depend upon the height of the cold water storage above it that is used to replenish the cylinder. The height difference is known as “Head”. 10metres in height generates 1 bar of pressure. In a normal home the height difference is usually only 2 meter’s or so resulting in 0.2 bar pressure hot water with resultant flow and pressure issues.

The unvented cylinder provides a solution to the low pressure and flow rate issues.

The unvented cylinder is fed directly from the cold main passing through a pressure reducing valve to restrict pressure usually to 3 bar. A balanced cold supply to the household can be taken off at this point.

Instead of a vent pipe the unvented cylinder has a temperature and pressure relief valve to provide an external safety outlet against excess temperatures and pressures. It also has an expansion relief safety valve to allow for excess expansion.

Unvented cylinders tend to be of two main types, either “Bubble Top” or with an external expansion vessel. The bubble top types have either an air bubble in the top or a moving diaphragm with air above it to allow for expansion as the water in the cylinder gets hot. The external types have a separate expansion vessel to provide for this expansion.

It is normally recommended that a minimum inlet water flow rate of 20 liters per minute is available to run an unvented cylinder.

The distinct advantage of the unvented cylinder is the high hot water flow rates achievable and their ability to cope with shock demand.

They are more expensive than the combination boiler route as they are usually fitted with a system boiler and associated external controls. However the cost of unvented cylinder has fallen dramatically over the last few years.

Unvented cylinders can only be worked upon or installed by engineers with G3 Building regulations qualification.