System Boilers

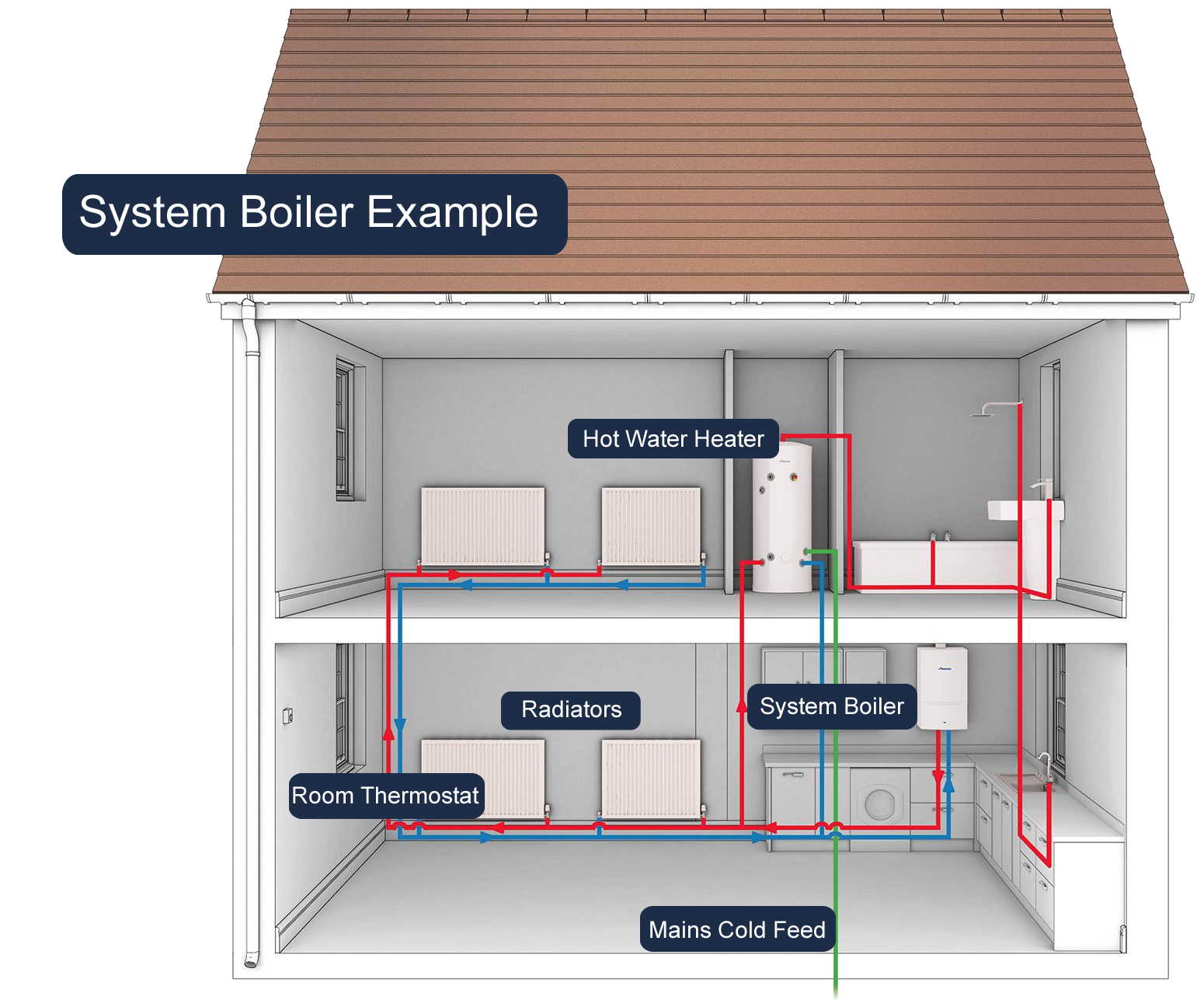

System boilers are typically used in conjunction with a hot water cylinder and a central heating circuit to provide hot water and heating.

This is the same as for a heat only boiler but the system boiler is usually installed on a pressurized primary heating and hot water circuit.

Instead of using a feed and expansion tank to provide a filling point the system boiler uses a filling loop from the cold main to fill the primary heating circuits. This is often internal to the boiler or one is fitted externally where not provided by the boiler manufacturer.

Instead of a vent pipe the system boiler on a pressurized system has a pressure relief valve connected to an external discharge pipe to protect against excess pressure.

The system boiler usually has the circulating pump internally as part of the boiler eqipment.

Control of the system boiler is very much as with a heat only boiler, using room and cylinder thermostats together with a timer/programmer and motorized valves to control the flow of hot water from the boiler.

Modern systems tend to utilize two, two port zone valves (“S Plan”) to control water to the heating and hot water cylinder.

System boilers can be used on most heating and hot water systems including unvented hot water cylinders and under floor heating systems as well as the traditional cylinder and radiator systems.

System boilers available today are condensing boilers.